Raw BMK data extracted from 2D CAD layout showing unstructured component designations and connections

Example of inconsistent BMK data formats requiring manual processing and validation

Electrical Design. Automation and Planning Department

Automated conversion of BMK data from various sources into Excel formats for seamless processing in control systems and E-CAD.

Projekt

BMK Tool: Automated Conversion of Designation Data into Excel

Kategorie

Electrical Design. Automation and Planning Department

Aufgaben im Projekt

Technologien

Python, Pandas, OpenPyXL, Excel

1/4

BMK data is often unstructured – in the form of text files, JSON, or inconsistent Excel sheets. Manually compiling and preparing the data is error-prone and leads to delays and inaccuracies in complex projects. An automated solution capable of handling all formats from a single data source is missing.

2/4

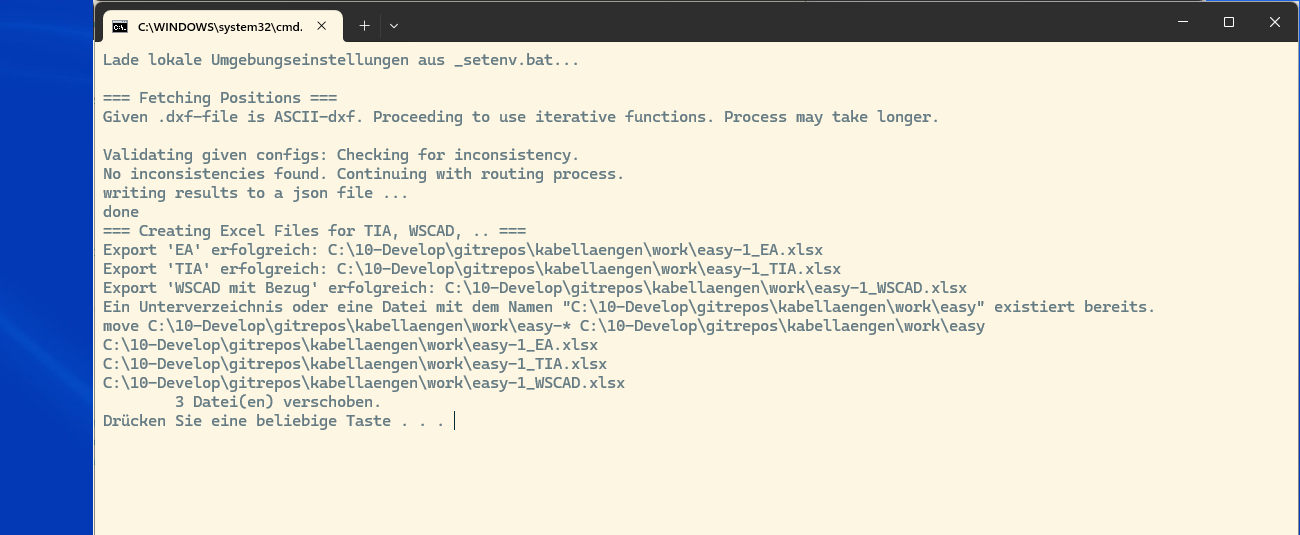

Development of a Python tool that analyzes raw BMK data from a 2D DXF plant layout, categorizes it, and automatically exports it into formatted Excel files. Common formats such as TIA Portal, WSCAD, and basic I/O overviews are supported. Company-specific formats can be added upon request.

The tool can be integrated into existing workflows and is flexibly configurable to meet different project requirements.

3/4

Raw data is read, matched against patterns, and categorized. Invalid entries and duplicates are automatically captured and documented in separate Excel sheets. This enables early error handling during processing.

The tool generates not only simple I/O overviews but also PLC-compliant ‘Constants’ and ‘PLC Tags’ for TIA Portal as well as specially formatted WSCAD exports with or without reference information.

Parameters such as mode (EA, TIA, WSCAD), input/output directories, and naming conventions are fully configurable to suit various project requirements.

The tool significantly reduces manual effort and ensures consistent, error-free BMK lists as a solid basis for control system programming and documentation.

4/4

The automated processing of BMK data saves time and minimizes error sources in the creation of control and E-CAD documents. Through flexible export formats, the tool can be seamlessly integrated into further systems such as Siemens TIA Portal or WSCAD. The quality and traceability of equipment identification data has been significantly improved, which shortens project timelines and enhances planning quality.

Michael Stangl

Managing Director