2/4

Concept & Planning

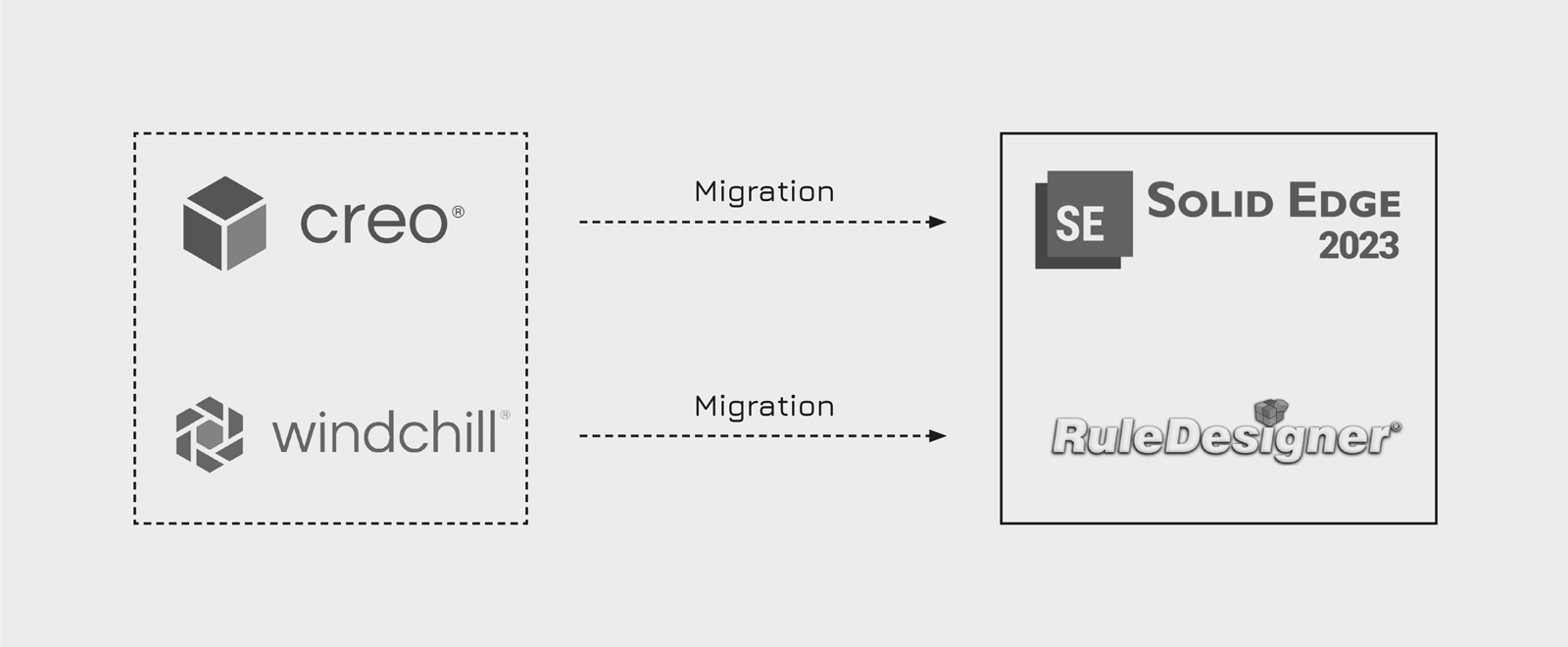

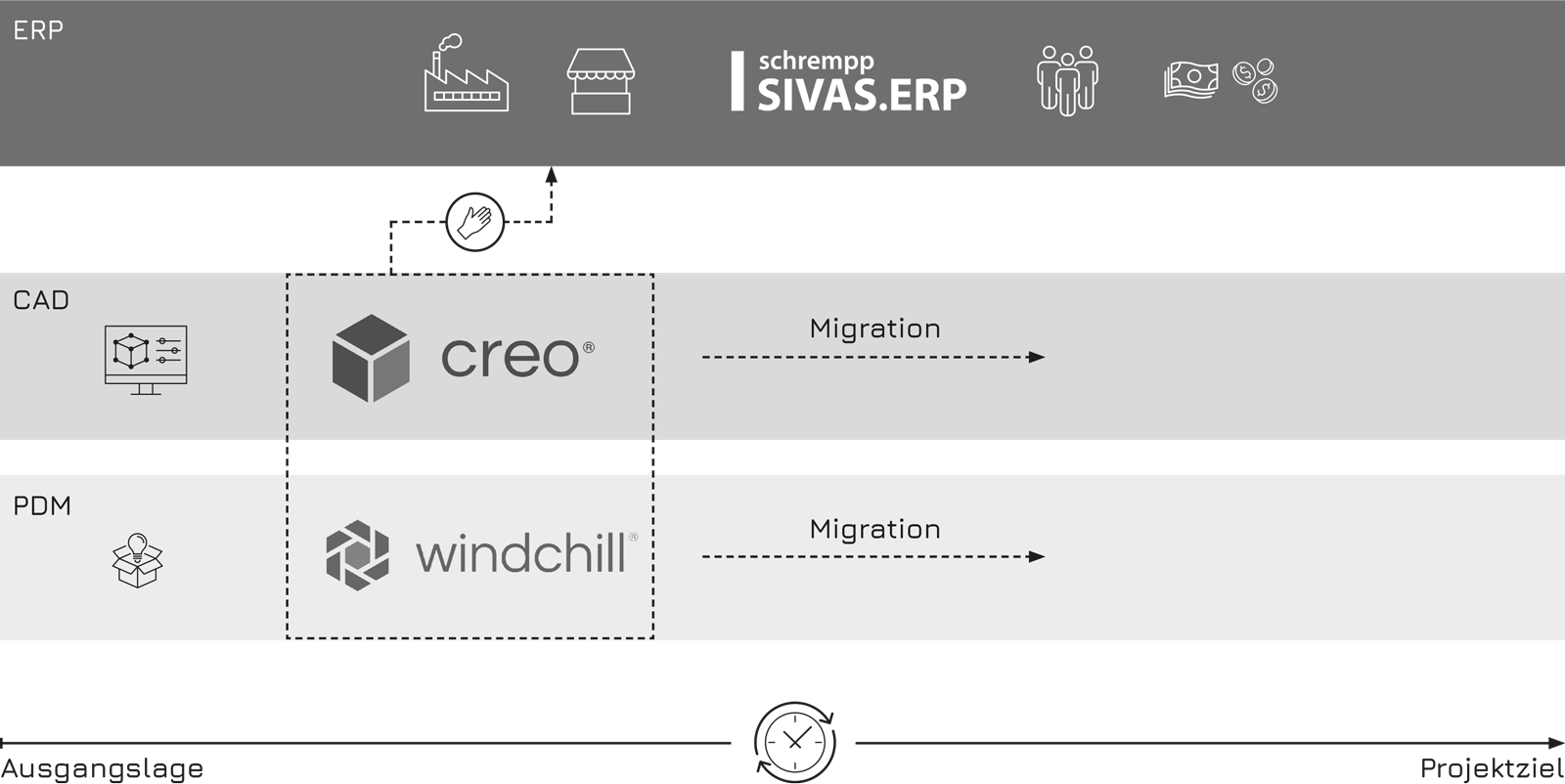

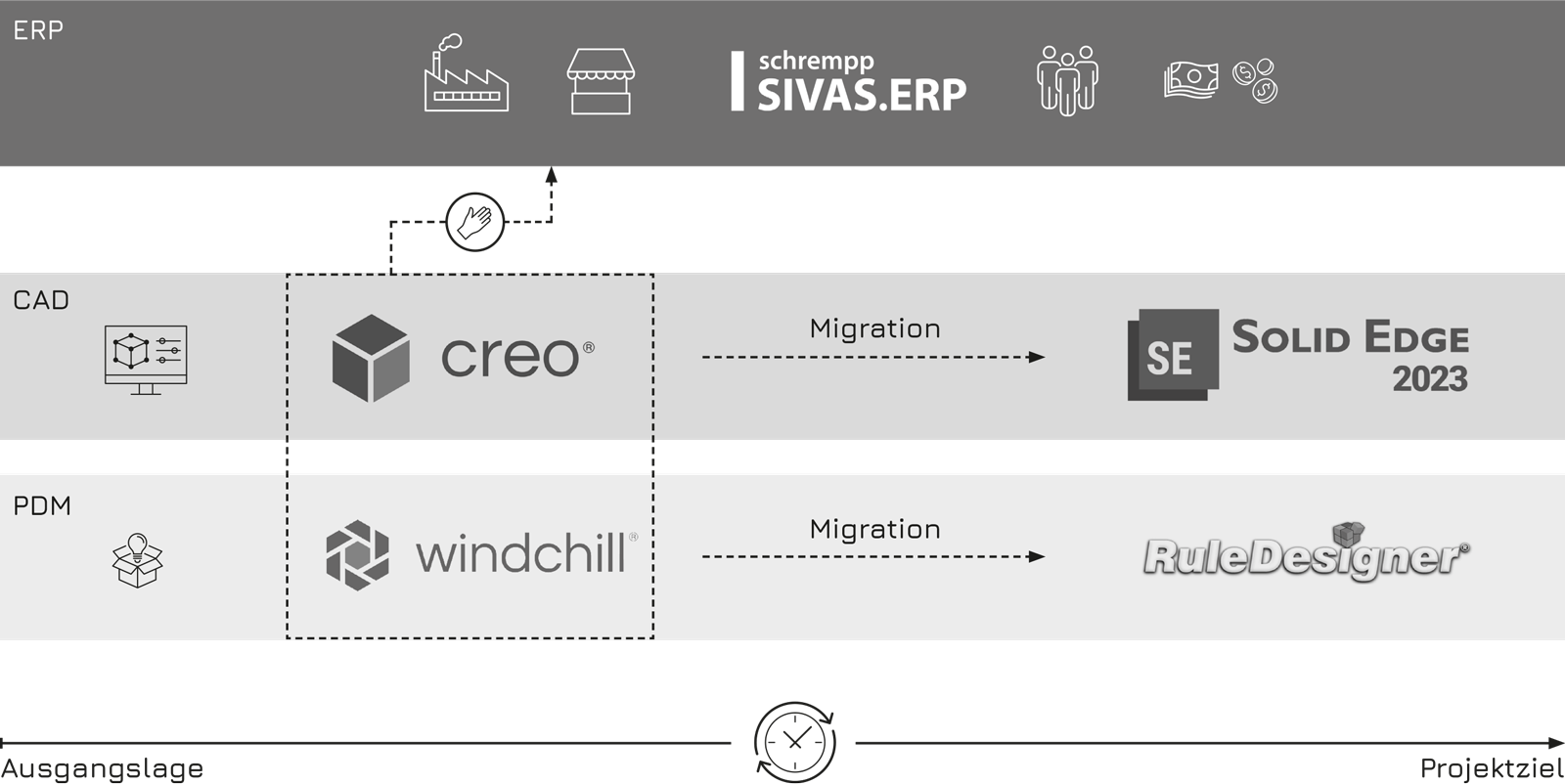

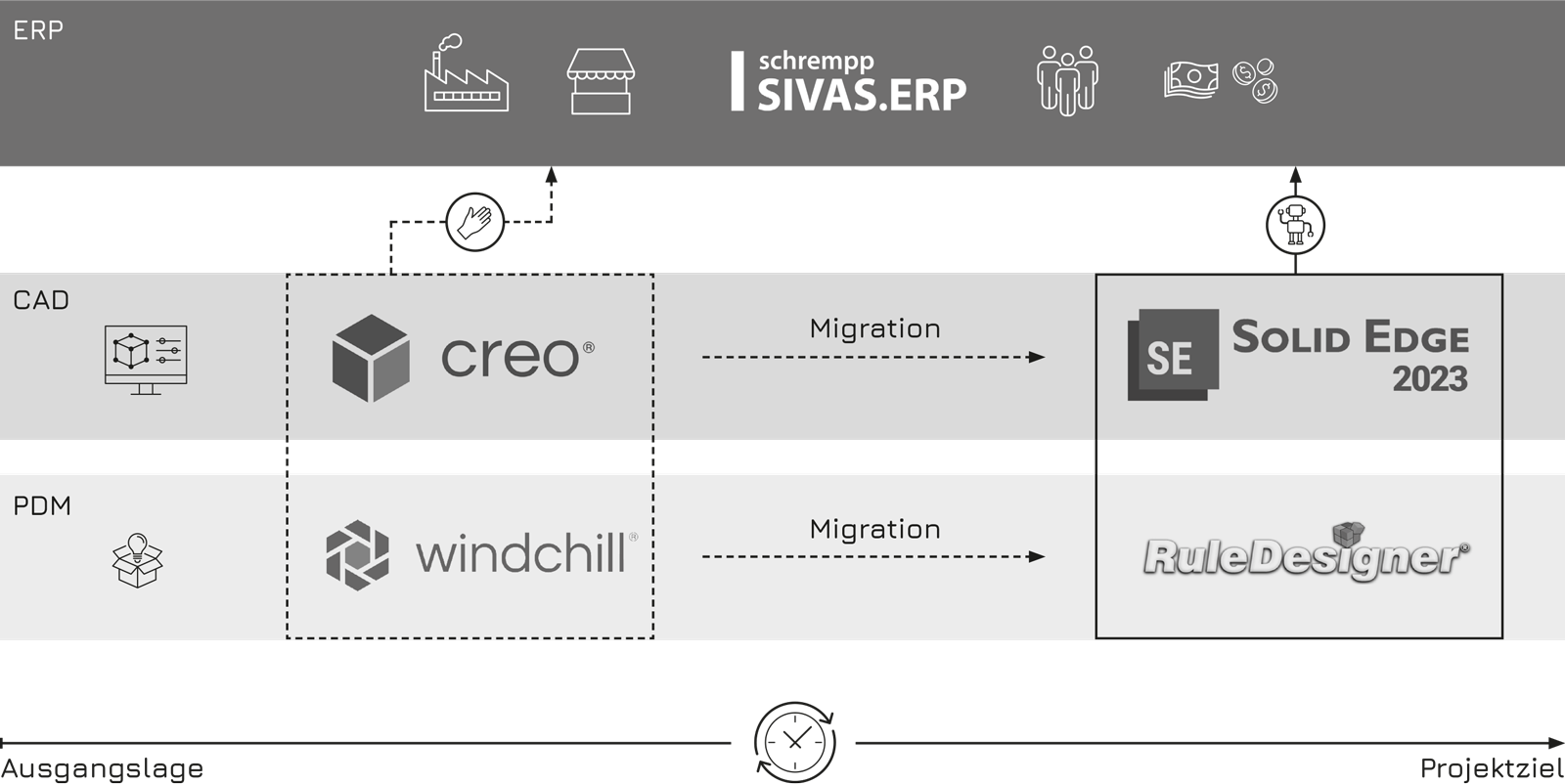

A concept for migrating the legacy data (approx. 30,000 files) was developed. First, the requirements for the new CAD and PDM systems were gathered to compare available solutions. Various complex assemblies were used as references, representing typical designs within the company. Potential simplifications provided by the new systems were evaluated with respect to their integration into the existing infrastructure. For example, a bidirectional connection with the ERP was ultimately ruled out due to complexity and effort.

1. Decision Process

- Evaluation and testing of various CAD and PDM providers

- Trial migration of selected legacy data as a reference

- Fit against the requirements list

2. Concept Development

- Requirements catalog for the new systems

- Analysis of existing system interfaces (e.g., ERP, drawing archive)

- Evaluation of possible ERP integration scenarios

3. Solution

The legacy CAD and PDM systems were replaced. Information from the design department now flows automatically into the ERP system without manual input.